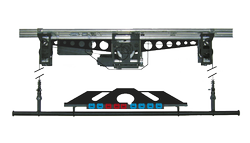

Modular Climber Plural

Modular Hoist

with pile winding system and four steel bands as load carriers. The moving part of the hoist is a pipe batten/ connector strip assembly with (4) lighting circuits plus (1) DMX connection to suspend lighting fi xtures in studio and theaters. Addition circuits or data lines are available as option. The smooth surface of the maintenance free steel bands result in a very quiet and shock free operation even at high speeds. The innovative steel band drive system is substantially smaller the conventional drives with steel cables due to the smaller drum diameter. The Plural is furnished with overload and underload detection, adjustable operating limits plus over travel limits. The motor control box with the load sensors and limit switches is conveniently located at the outside of the motor gear unit and includes a push button for emergency operation. The lifting capacity is for even distributed loads or single point loads between the steel bands the same.Control the Plural

Use of steel bands as carriers

Advances in materials engineering have facilitated the production of high-strength spring steels which were beyond our imagination even a short time ago. Steel bands can be coiled one on top of the other, allowing highly compact designs of hoisting equipment. Where frequency converters are used, algorithms automatically control the drive speed, which would otherwise vary with the change in circumference as steel bands are coiled and uncoiled respectively. The smooth surface of steel bands ensures that drives using this technology operate at significantly less noise than conventional carriers. The rounded edges also result in an extremely slim profi le, which keeps stage light refl ections, which are unavoidable with conventional carriers (such as chains or steel cables) to a minimum. Steel bands are therefore hardly noticeable during shows. In addition, individual loads do not twist when suspended from steel bands, whereas this can occur with steel cables due to the standard wire geometry of such cables. Also, steel bands do not elongate or bounce. The steel bands used by ASM are non-wearing during operation. Reduced service and rnaintenance costs therefore constitute an additional advantage. Upon request steel band carriers can be supplied with black plastic lamination.

|

Type |

Over-grid |

Over-grid |

Grid |

Grid |

Self-climber |

Self-climber |

|

Extension max. (mm) |

14000 |

10000 |

14000 |

10000 |

14000 |

10000 |

|

Suspension element |

4x Steel band |

4x Steel band |

4x Steel band |

4x Steel band |

4x Steel band |

4x Steel band |

|

Load attachment |

48,3 mm pipe |

48,3 mm pipe |

48,3 mm pipe |

48,3 mm pipe |

48,3 mm pipe |

48,3 mm pipe |

|

Payload max. (kg) |

130 |

150 |

130 |

150 |

100 |

130 |

|

Motor |

230/400 V, 50 Hz |

230/400 V, 50 Hz |

230/400 V, 50 Hz |

230/400 V, 50 Hz |

230/400 V, 50 Hz |

230/400 V, 50 Hz |

|

Motor protection |

IP54 |

IP54 |

IP54 |

IP54 |

IP54 |

IP54 |

|

Gear box |

dynamically self-locking drive |

dynamically self-locking drive |

dynamically self-locking drive |

dynamically self-locking drive |

dynamically self-locking drive |

dynamically self-locking drive |

|

Limit switch bottom/top |

yes |

yes |

yes |

yes |

yes |

yes |

|

Ultimate limit switch bottom/top |

yes |

yes |

yes |

yes |

yes |

yes |

|

Slack rope detection |

yes |

yes |

yes |

yes |

yes |

yes |

|

Lifting speed max. (mm/s) |

250 |

250 |

250 |

250 |

250 |

250 |

|

Net weight (kg) |

ca. 105 |

ca. 100 |

ca. 105 |

ca. 100 |

ca. 110 |

ca. 105 |

|

Power cable |

5x 2.5 qmm; 4x DMX |

5x 2.5 qmm; 4x DMX |

5x 2.5 qmm; 4x DMX |

5x 2.5 qmm; 4x DMX |

5x 2.5 qmm; 4x DMX |

5x 2.5 qmm; 4x DMX |

|

Power connector at the top |

open |

open |

open |

open |

open |

open |

|

Power connector at the bottom |

Schuko |

Schuko |

Schuko |

Schuko |

Schuko |

Schuko |

|

Order code |

1002760 |

1002770 |

1002780 |

1002790 |

1002800 |

1002810 |